Insights into the Manufacturing of Fuel Tank Crash Test Simulation Systems

99exch.com login, laser247 com, yolo 24/7 login:Insights into the Manufacturing of Fuel Tank Crash Test Simulation Systems

If you’ve ever wondered how fuel tank crash test simulation systems are made, you’re in luck. In this article, we’ll delve into the intricate process of manufacturing these systems, shedding light on the key components, materials, and technologies involved.

Overview of Fuel Tank Crash Test Simulation Systems

Fuel tank crash test simulation systems are crucial for ensuring the safety and performance of vehicles in the event of a collision. These systems are designed to replicate real-world crash scenarios, allowing engineers to assess the structural integrity of fuel tanks and their components. By subjecting fuel tanks to controlled impact forces, manufacturers can evaluate their durability, strength, and resistance to deformation.

Key Components of Fuel Tank Crash Test Simulation Systems

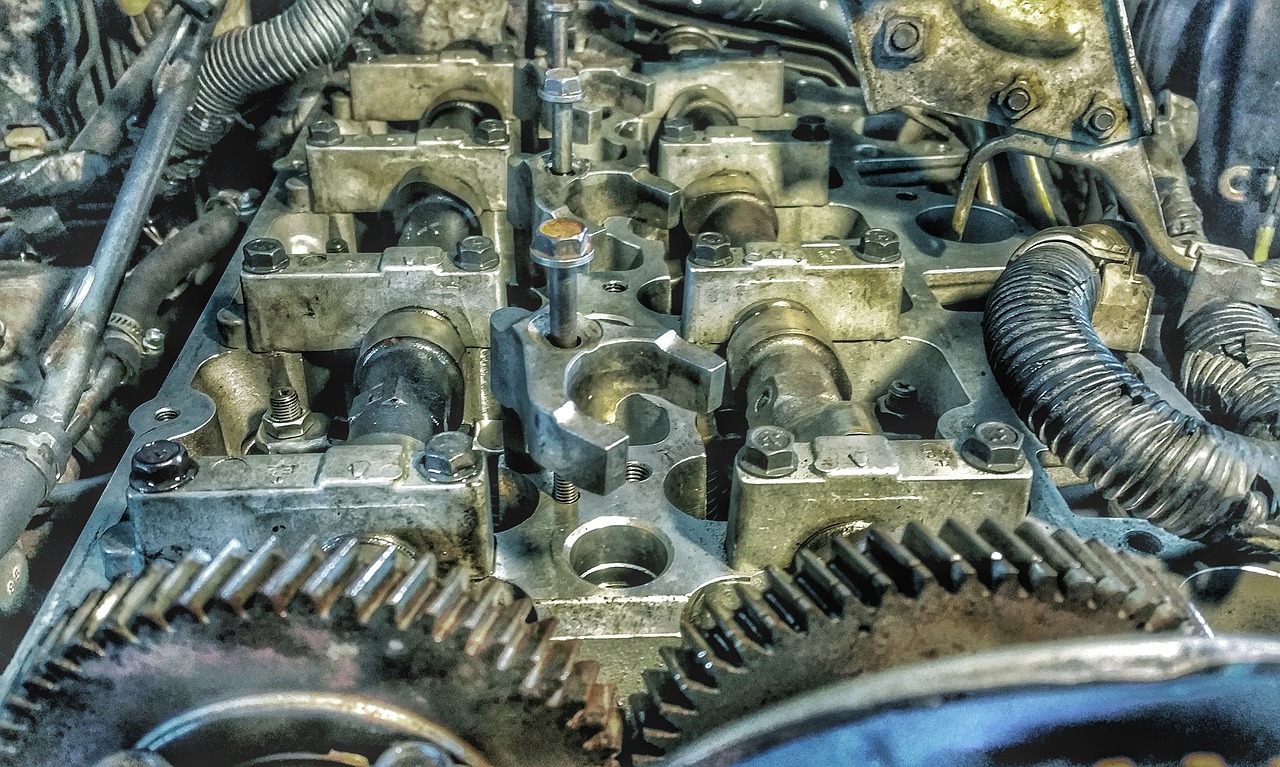

One of the key components of a fuel tank crash test simulation system is the impactor, which is used to deliver precise and controlled forces to the fuel tank during a crash test. Impactors are typically made of high-strength materials such as steel or aluminum, and are designed to mimic the impact forces experienced in actual collisions.

Another essential component of these systems is the data acquisition system, which is responsible for recording and analyzing crucial data during crash tests. This system captures information such as impact forces, deformation patterns, and structural integrity, providing valuable insights into the performance of the fuel tank under duress.

Materials Used in Manufacturing Fuel Tank Crash Test Simulation Systems

The materials used in manufacturing fuel tank crash test simulation systems are chosen for their strength, durability, and reliability. Steel is commonly used for the construction of impactors, due to its high tensile strength and resistance to deformation. Aluminum is also a popular choice for certain components, as it is lightweight and possesses excellent impact absorption properties.

In addition, advanced composite materials such as carbon fiber are increasingly being used in the production of fuel tank crash test simulation systems. These materials offer superior strength-to-weight ratios, making them ideal for applications where weight reduction is critical.

Technologies Involved in Manufacturing Fuel Tank Crash Test Simulation Systems

Modern fuel tank crash test simulation systems are equipped with a range of advanced technologies to enhance their performance and accuracy. High-speed cameras are used to capture detailed footage of crash tests, allowing engineers to analyze the behavior of the fuel tank in slow motion.

Finite element analysis (FEA) software is also employed to simulate crash scenarios and predict the structural response of fuel tanks under different impact conditions. This technology enables manufacturers to optimize the design of fuel tank crash test simulation systems, ensuring their effectiveness and reliability.

Challenges and Innovations in the Manufacturing Process

One of the main challenges in manufacturing fuel tank crash test simulation systems is ensuring the accuracy and repeatability of crash tests. Engineers must carefully calibrate all components of the system to deliver consistent impact forces and capture reliable data.

To overcome these challenges, manufacturers are constantly innovating and refining their manufacturing processes. The integration of artificial intelligence and machine learning algorithms is revolutionizing crash test simulation systems, enabling real-time adjustments and optimization during tests.

Moreover, the use of additive manufacturing techniques, such as 3D printing, is allowing for the rapid prototyping and customization of components for fuel tank crash test simulation systems. This technology is enhancing the speed and flexibility of manufacturing processes, while reducing costs and waste.

In conclusion, fuel tank crash test simulation systems play a crucial role in ensuring the safety and performance of vehicles on the road. By understanding the key components, materials, and technologies involved in manufacturing these systems, we can appreciate the complexity and precision required to conduct accurate and reliable crash tests.

FAQs

Q: How are impact forces controlled in fuel tank crash test simulation systems?

A: Impact forces are controlled through the design and calibration of the impactor, as well as the configuration of the test setup.

Q: What safety measures are in place during crash tests?

A: Crash tests are conducted in controlled environments with safety measures such as protective barriers, remote operation, and emergency shutdown systems.

Q: How long does it take to manufacture a fuel tank crash test simulation system?

A: The manufacturing process can vary depending on the complexity and customization of the system, but it typically takes several weeks to complete.

Q: Are fuel tank crash test simulation systems reusable?

A: Yes, most systems are designed to be reusable for multiple tests, with components that can be replaced or refurbished as needed.

Q: How accurate are crash test simulations compared to real-world collisions?

A: Crash test simulations provide valuable insights into the behavior of fuel tanks under impact conditions, but they may not fully replicate the complexity of real-world collisions. However, they are essential for evaluating and improving the safety of vehicles.